KTY8-350

The cutter bit is of 90 degree rotation,and its rake angle is 45 degree.The working table can rotate within the range of 0-360 degree in the horizontal direction,and turnover within the range of 0-85 degree in the vertical direction.The machine head travels and the beam travels using linear guides, servo drive control, faster travel speed and higher precision;For it's one-piece structure,with the advantages of small size,convenient to install and move,easy to operate etc.

Package & Shipping

Package: air bubble film

After-sales Service

One year warranty

FAQ

Payment terms:30% Deposit,70% Balance Payment

Delivery time:30 days after deposit payment

- Maximum Diameter of Sawpit: Φ350-Φ400mm

- Rotation Angle of Worktable(Optional): 0~360°

- Maximun Processing Size: 3200×2000mm

- Rotation of Cutter Shaft: 0°、90°

- Maximum Up-Down Travel of Cutter: 0~240mm

- Rake Angle of Cutter: 0°、45°

KTY9-350

Cutter Head:

● The cutter head is engineered for versatility, capable of rotating a full 90°, enabling precise vertical and horizontal cuts. It also tilts up to 45°, allowing for intricate angled cuts such as bevels and chamfers, making it ideal for complex designs and edge work.

Worktable

● Two worktable configurations are available:

1. Non-rotating: A stable, fixed option for straightforward cutting tasks.

2. Rotating and tilting: This advanced option allows the worktable to rotate 360°, enabling precise positioning of the stone. Additionally, it tilts vertically from 0° to 85°, facilitating easy loading and unloading of slabs while accommodating various cutting angles for improved cutting efficiency on thicker materials.

Movement System

● The machine utilizes precision linear guide rails for smooth and controlled movement of the cutting head and beam, ensuring high accuracy in every cut.

● A high-performance servo drive system powers the head and beam, providing rapid acceleration and deceleration, while maintaining stability during motion. This results in more precise, consistent cuts, even at high speeds.

Motor

● A high-power, water-cooled motor drives the cutting process, delivering smooth, uninterrupted cutting across a wide range of materials. The motor's integrated water-cooling system ensures optimal temperature control, protecting the motor from overheating and extending its operational life during long cutting sessions.

Operation

● The machine features an intuitive control system designed for ease of use. The operator can quickly switch between different cutting modes, such as orthogonal cutting for straight cuts and chamfering for angled cuts. These modules enable fully automated processing, reducing manual input and increasing production efficiency.

Tool Adjustment:

● An electronic handwheel allows for precise fine-tuning of the cutting tool, ensuring accurate positioning and depth control. This feature enhances the machine's ability to handle intricate cutting tasks that require minute adjustments.

- Maximum Diameter of Sawpit: Φ350~Φ400mm

- Rotation Angle of Worktable(Optional): 0~360°

- Maximun Processing Size: 3600×2000mm

- Rotation of Cutter Shaft: 0°、90°

- Maximum Up-Down Travel of Cutter: 0~240mm

- Rake Angle of Cutter: 0°、45°

KTY3-350

It adopts the technology of microcomputer control,infrared cutting,and hydraulic rotation.The working table can rotate within the range of 0-360 degree in the horizontal direction,and rotates within the of 0-85 degree in the vertical direction.For it's one-piece structure,with the advantages of high precision,convenient to install and adjust,easy to operate etc.

Package & Shipping

Package: air bubble film

After-sales Service

One year warranty

FAQ

Payment terms:30% Deposit,70% Balance Payment

Delivery time:30 days after deposit payment

- Maximum Diameter of Sawpit: Φ350~Φ400mm

- Maximun Processing Size: 3200x2000mm

- Maximum Up-Down Travel of Cutter: 230mm

- Cutting Thickness: 0~80mm

- Rotation Angle of Worktable(Optional): 0~360°(0°/45°/90°/180°/270°)

- Power of Main Motor: 15KW

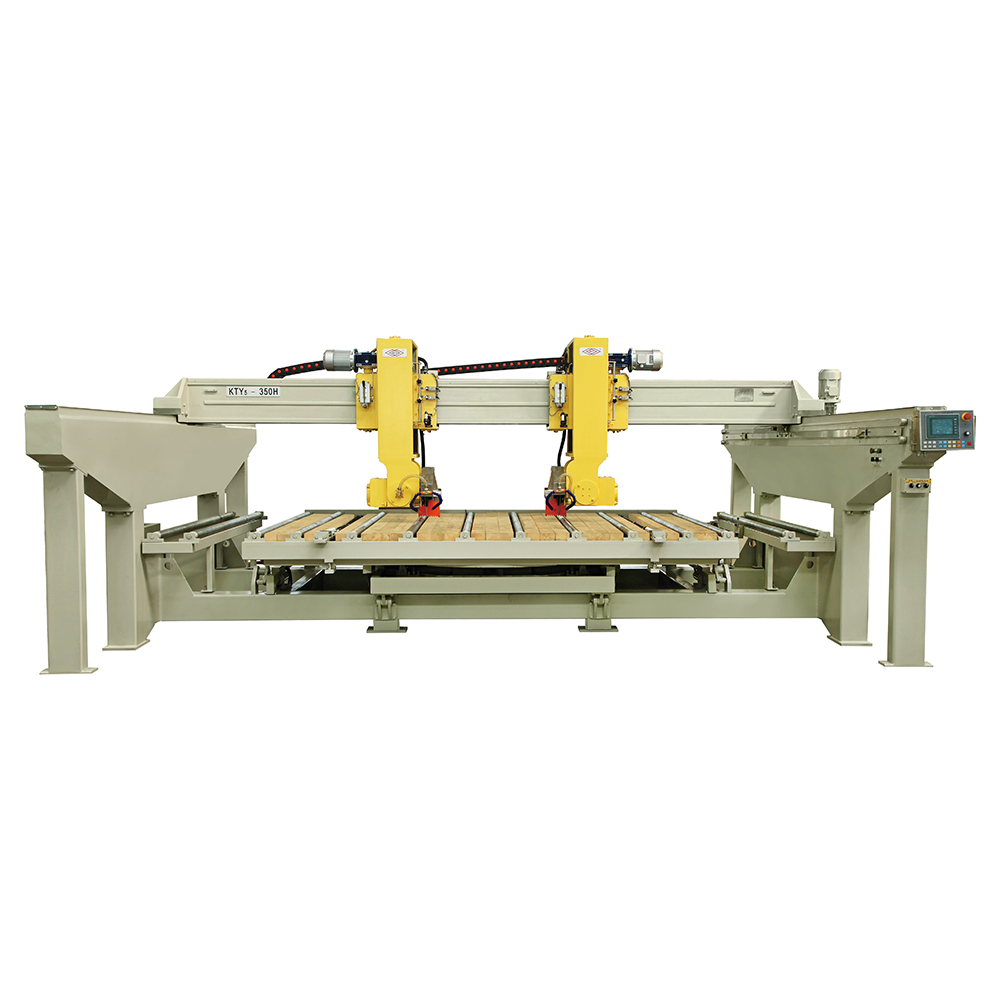

KTY5-350H

Controlled by microcomputer,KTY5-350H is equipped with water cooling spindle motor and its worktable can rotate 0 to 90 degree horizontally.The feeder will convey the slab onto worktable and do autolocation.It can cut slab by one cutter or two cutters at the same time.It is specially suitable for the cutting of manmade quartz or microcrystalline slabs.With one piece structure,the machine is of advantage such as simple operation,high efficiency,small size,easy transport,easy installation and adjustment.

Package & Shipping

Package: air bubble film

After-sales Service

One year warranty

FAQ

Payment terms:30% Deposit,70% Balance Payment

Delivery time:30 days after deposit payment

- Maximum Diameter of Sawpit: Φ350~Φ400mm

- Maximun Processing Size: 3250×1900mm/3550×2200mm

- Maximum Up-Down Travel of Cutter: 240mm

- Cutting Thickness: 0~80mm

- Air Pressure: 0.4~0.6MP

- Inlet hole demension: 1950mm/2300mm

KTY2-350

The cutter bit is of 90 degree rotation,and its rake angle is 45 degree.The working table can rotate within the range of 0-360 degree in the horizontal direction,and turnover within the range of 0-85 degree in the vertical direction.For it's one-piece structure,with the advantages of small size,convenient to install and move,easy to operate etc.

Package & Shipping

Package: air bubble film

After-sales Service

One year warranty

FAQ

Payment terms:30% Deposit,70% Balance Payment

Delivery time:30 days after deposit payment

- Maximum Diameter of Sawpit: Φ350~Φ400mm

- Maximun Processing Size: 3200x2000mm

- Maximum Up-Down Travel of Cutter: 250mm

- Cutting Thickness: 0~80mm

- Rotation Angle of Worktable(Optional): 0~360°

- Rotation of The Cutter Shaft: 0/90°

KTY1-350

This machine is mainly used for cutting and processing marble and granite slabs.For it's one-piece structure,it has several advantages,such as small size,convenient to transit,install and adjust,high precision,also easy to operate.What's more,it saves time and cost to build concrete cement base,especially suitable for customers in small plant and always work with moving plant.

Package & Shipping

Package: air bubble film

After-sales Service

One year warranty

FAQ

Payment terms:30% Deposit,70% Balance Payment

Delivery time:30 days after deposit payment

- Maximum Diameter of Sawpit: Φ350~Φ400mm

- Maximun Processing Size: 3200x2000mm

- Maximum Up-Down Travel of Cutter: 230mm

- Cutting Thickness: 0~80mm

- Rotation of Cutter Shaft: 0/90°

- Power of Main Motor: 11KW

KTY1-350H

This machine adopts advanced technologies such as microcomputer control,automatic zero return infrared guiding,and water cool spindle motor etc,the cutter head of this machine can be horizontal 90° rotating;equipping with hydraulic lifting feeding rotary drum on the worktable and feeding inlet in the side stand wall,this machine specially utilized as cutting block in the re-fabricated quartz stone,micro crystal stone slab production line with merits as one-piece structure,small size,convenient transportation,installation.

Package & Shipping

Package: air bubble film

After-sales Service

One year warranty

FAQ

Payment terms:30% Deposit,70% Balance Payment

Delivery time:30 days after deposit payment

- Maximum Diameter of Sawpit: Φ350~Φ400mm

- Maximun Processing Size: 3250x1900mm

- Maximum Up-Down Travel of Cutter: 250mm

- Cutting Thickness: 0~80mm

- Rotation of Cutter Shaft: 0/90°

- Inlet hole demension: 1950mm